NEW TO GRAVEL?

It can be challenging to decide where best to ride your new bike, especially if you want to expand your horizons with new areas and explore the country around you.

We put together some routes based here in Northern Ireland, and will aim to update this on a regular basis to help you download new routes and enjoy everything that this island has to offer!

Got a route that you want to share with other? Simply send us a link and a brief description of the ride, and we will upload for like-minded adventurers to discover.

BORDERLANDS 85KM

The Borderlands takes place every year and departs the village of Belcoo before taking in the forests and mountains on both sides of the Irish Border.

The 85km route takes in 1400m of elevation, but there are shorter 65km and 40km options during the event for those who want to take in the sights in less of a rush.

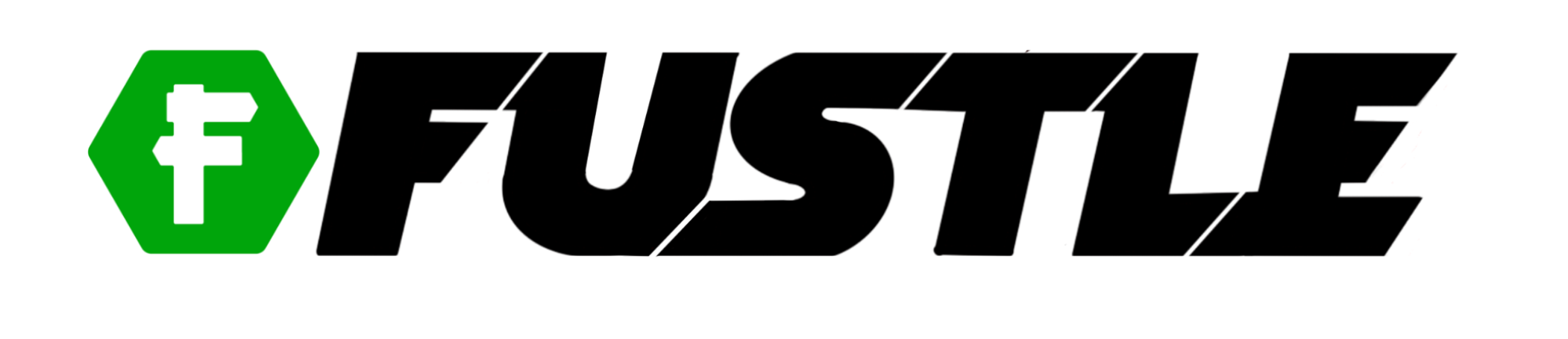

HELENS BAY - SCRABO

Used for our Fustle Family Ride 25.1 in APRIL 2025 , this route starts at the popular Helens Bay Beach car park, with ample parking, and toilet facilities right at the trail head.

This would be described as an itermediate route, suitable for most riders with some level of technical ability, and blends a mixture of off-road moderatly technical fireroad path with some quiet backroads and the odd hill climb thrown in.

It is a fantastic way to see different parts of the Ulster Way path and also the sights around Scrabo Tower.

Stats:

- Dist: 21 Miles

- Elevation: 1200ft

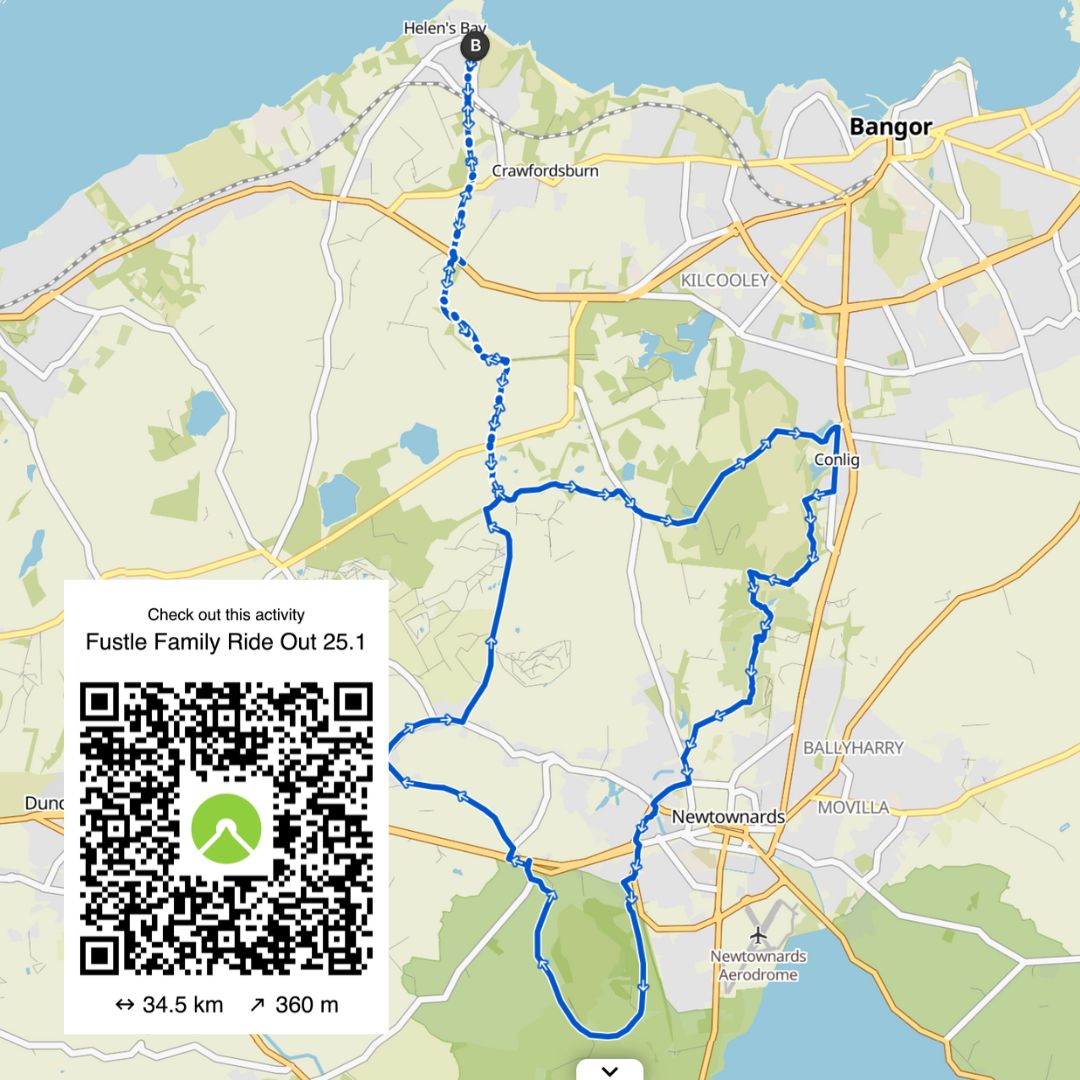

GLENARIFF FOREST PARK

Used for our Fustle Family Ride 24.3 in November 2024 , this route takes in the hills above Glenariff and contains approximately 14 miles of riding with around 1300ft of elevation.

This would be described as an itermediate route, suitable for most riders with some level of technical ability, and contains some road crossings and short road sections.

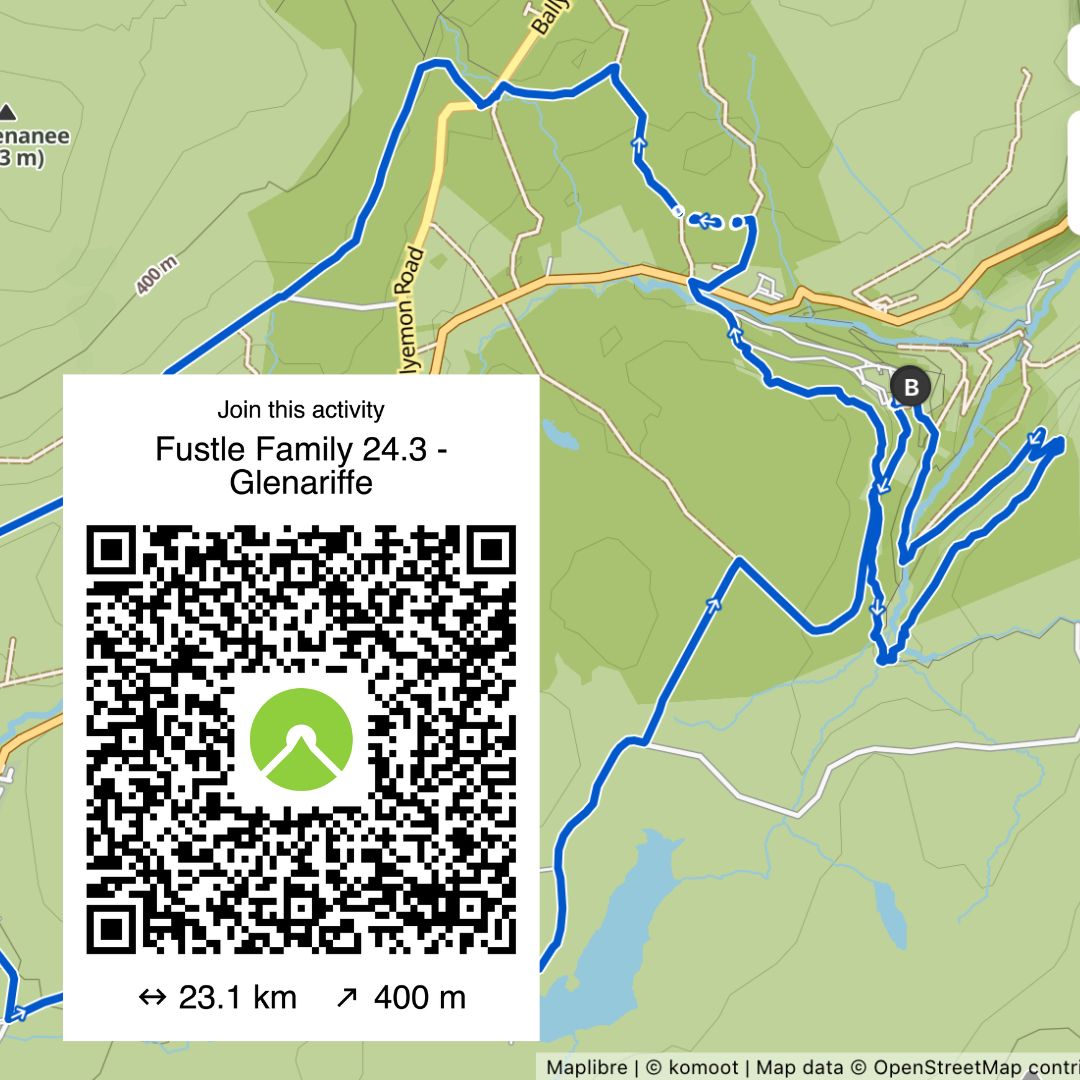

Helens Bay - Coastal - Greenway Circuit

A predominantly flat route and a great ride for beginners to intermediate riders, this 30 mile circuit is mainly away from traffic and takes in a mixture of cycle path, closed fireroads and a little bit of quiet tarmac road through the airport/dock area of Belfast.

Stats:

- Dist: 30.3miles

- Elevation: 1100ft