Ideal

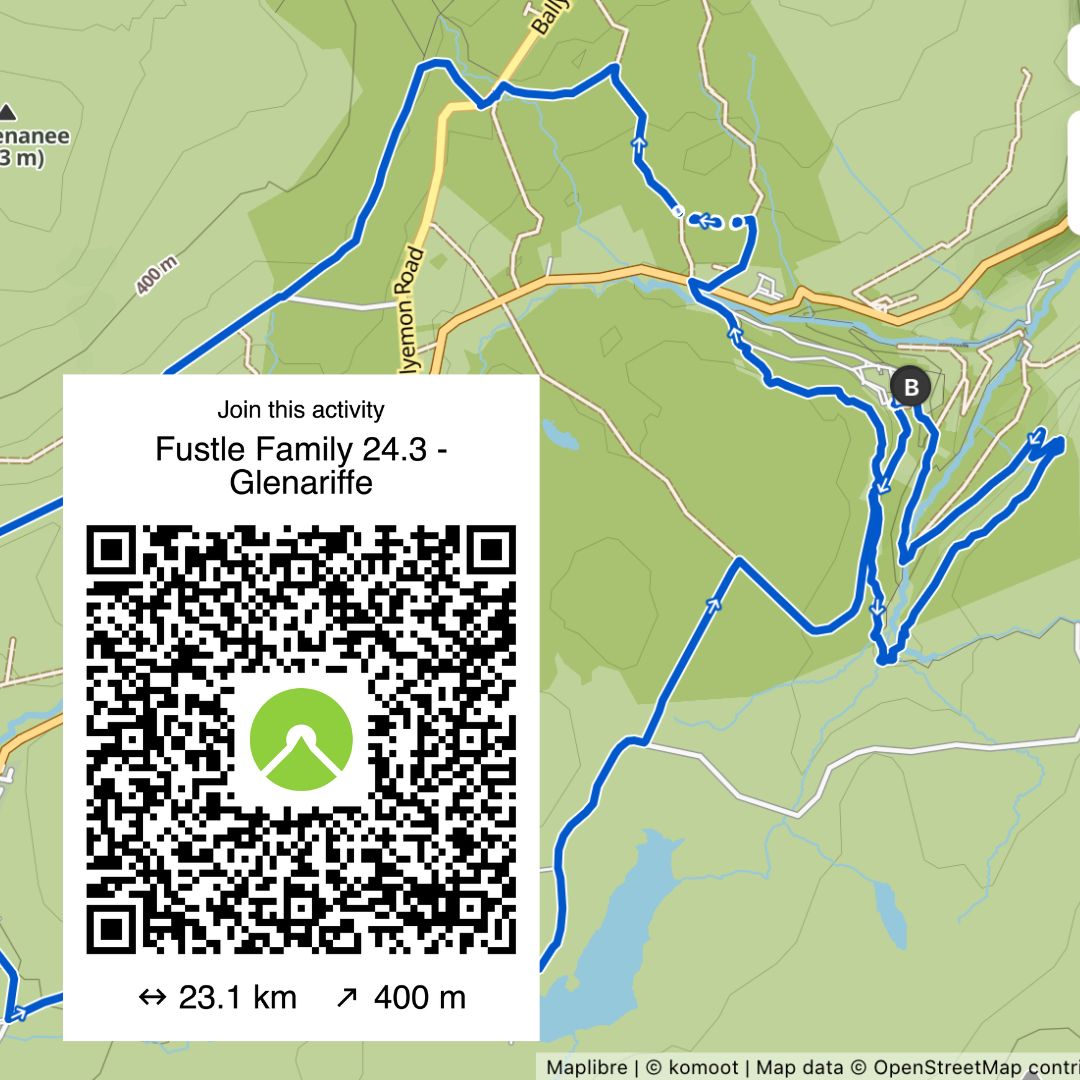

GLENARIFF FOREST PARK

Used for our Fustle Family Ride 24.3 in November 2024 , this route takes in the hills above Glenariff and contains approximately 14 miles of riding with around 1300ft of elevation.

This would be described as an itermediate route, suitable for most riders with some level of technical ability, and contains some road crossings and short road sections.